Merck Pharmaceuticals provides veterinary and healthcare services for the medical industry, world-wide. Deep in the urban heart of Mexico City, our team met with contractors where they expressed a need to expand one of their local facilities. They envisioned adding two new floors to one of their current buildings, which would create more real estate to meet their needs. The current structure at the time, however, couldn’t support the extra weight they calculated would be added to the current load. Additional re-enforcement to the foundation would be needed to support the new floor plan. Luckily, we were there to help.

DESIGNED & DELIVERED

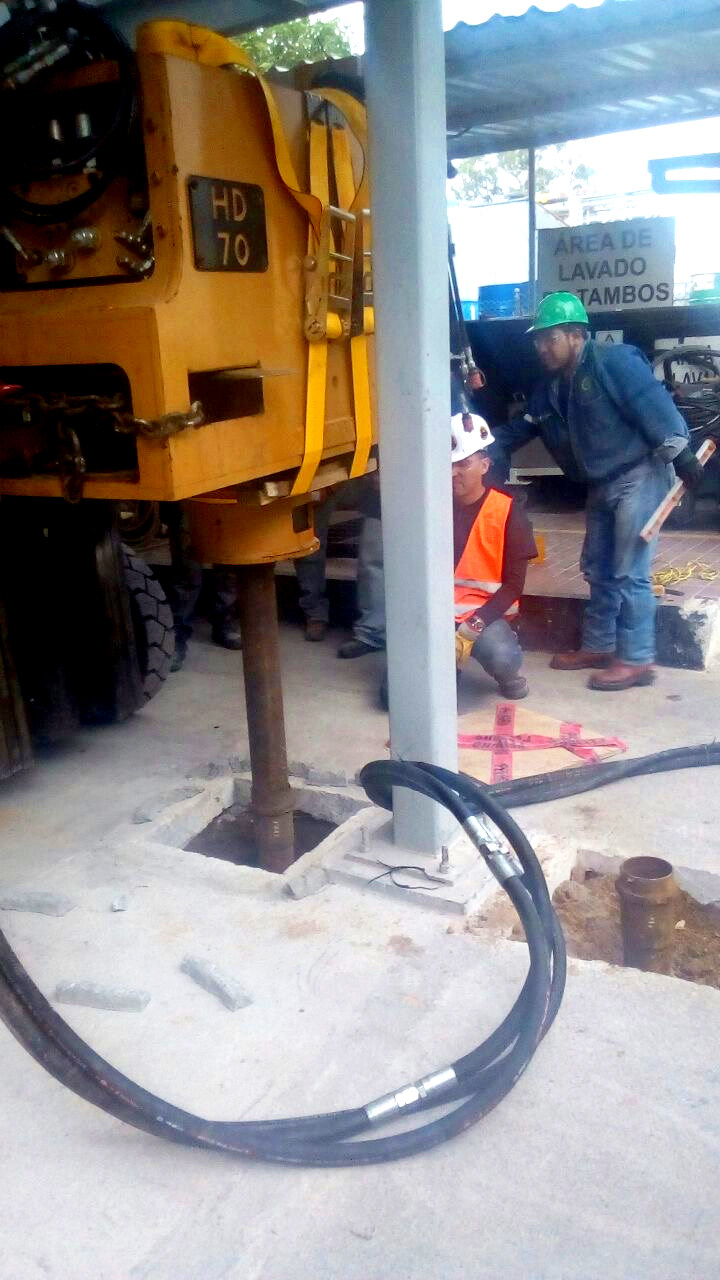

We quickly designed an improved foundation to meet their needs. With our veteran knowledge of deep foundations, even our modest designs were able to offer them the load capacities that exceeded their expectations. Their team happily agreed to the design, and the project was underway. Our rapid pile manufacturing process produced & shipped their helical pile order to the jobsite, along with a low-overhead configuration of American Piledriving Equipment’s HD70 driver. It was on the crisp morning of March 24th when the first pile installations started.

A LOW-OVERHEAD HELICAL PILE INSTALL SOLUTION BY APE

CLICK VIDEO ABOVE TO WATCH

Once inside the building, the low overhead space only allowed 7.5ft. maximum height for their crew to work in. They mounted APE’s HD70 onto a three-ton forklift, and powered the Driver using a CAT 320 excavator.

Made with T1 steel and rapid installation design, our threaded & coupled helical piles made their way into the ground with ease. Once the HD70 finished installation of a 4ft. a lead pile, the crew would grab and place an extension pile on top of it, then use HD70 to thread the extension pile it into the lead pile, combining the segments together to extend the completed pile length. The Driver would continue installing the pile into the ground, and this process would continue until they reached their target depth of over 50ft. below grade!

The installation crew installed a total of six completed heavy-walled 4.5” diameter helical piles 50ft. deep. Load tests confirmed that total load capacity per pile reached 110 Kips, and the total time it took per pile installation to target depth was within 30 minutes. Within a few days, from start to finish, the job was complete.

The jobsite was cleaned, cleared, and left with nothing but a new, re-enforced foundation that Merck could use to build their new floors, and even provide opportunities for future vertical expansion. The installation team expressed their deepest thanks to APE Mexico for the performance and reliability of their equipment, as well as to Pileworks for our rapid production & cost-saving benefits of our elite helical pile solutions.