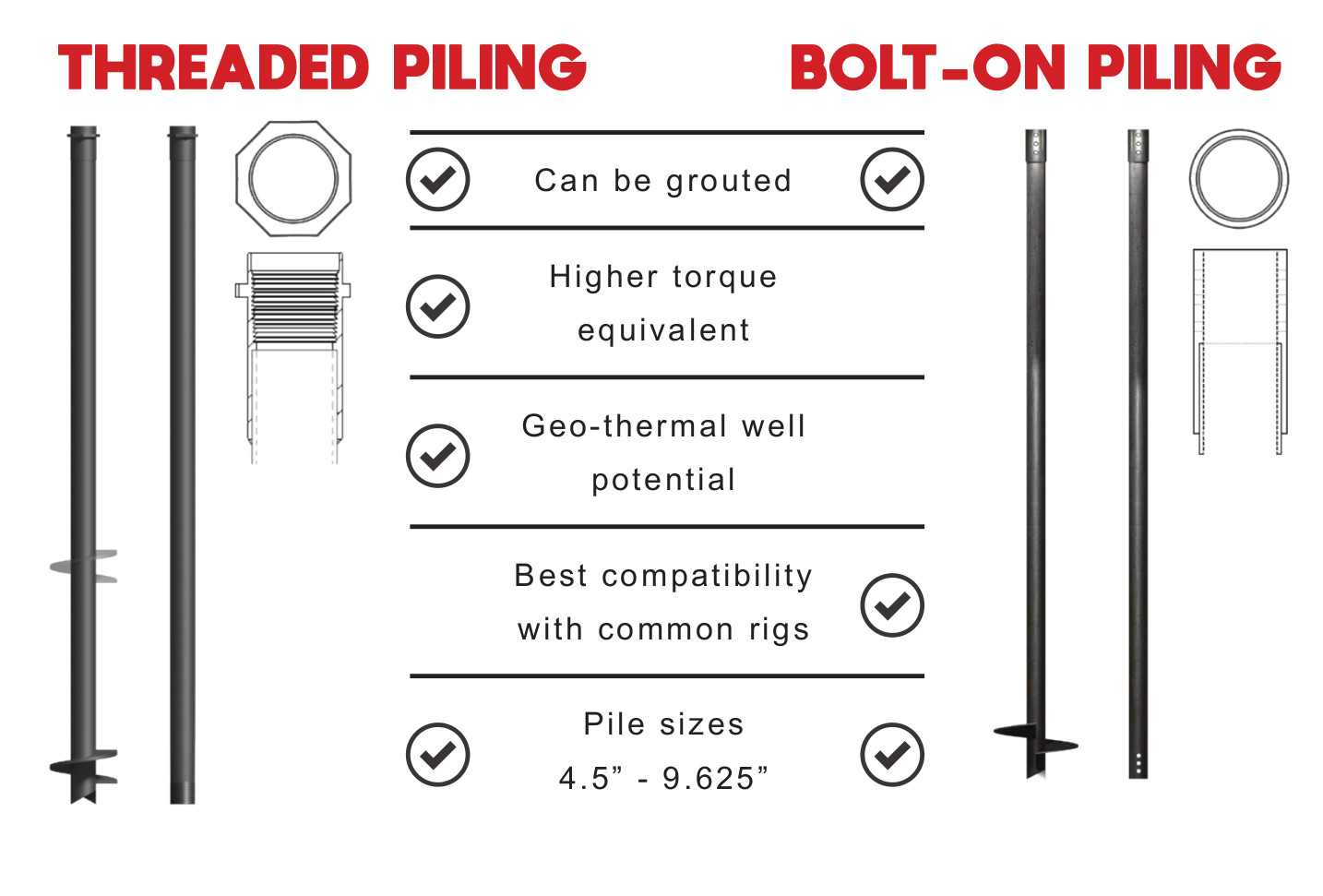

In construction, a project’s foundation is often the most overlooked element. Stronger foundations mean greater reliability against natural disasters, devastation, and wear over time. Pileworks provides the best, most affordable piling products in the construction industry. Buildings, bridges, utility towers, powerlines, and storage tanks are securely built on Pileworks anchors and foundations. Check out the advantages from each of our pile configurations.

ARE YOU A MANUFACTURER?

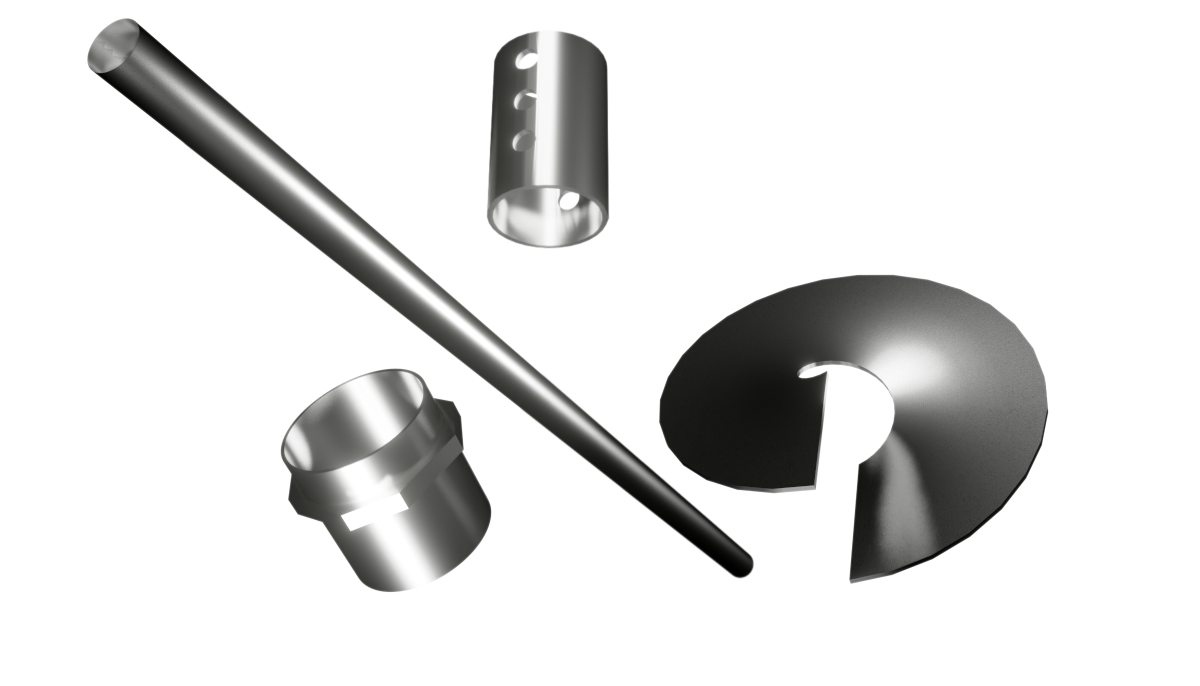

We are more than a direct supplier. We also help support your manufacturing needs, whether that be flights, pipe, couplings, even lab chemical and tensile testing.

MADE TO ORDER

No Minimum orders. Our parts are made exactly the way you need, ensuring faster production, rapid delivery, higher quality steel, and big savings on costs.

How our piles are made

FOR STRUCTURES

FOR POWERLINES

FOR TOWERS

KT CORRELATIONS

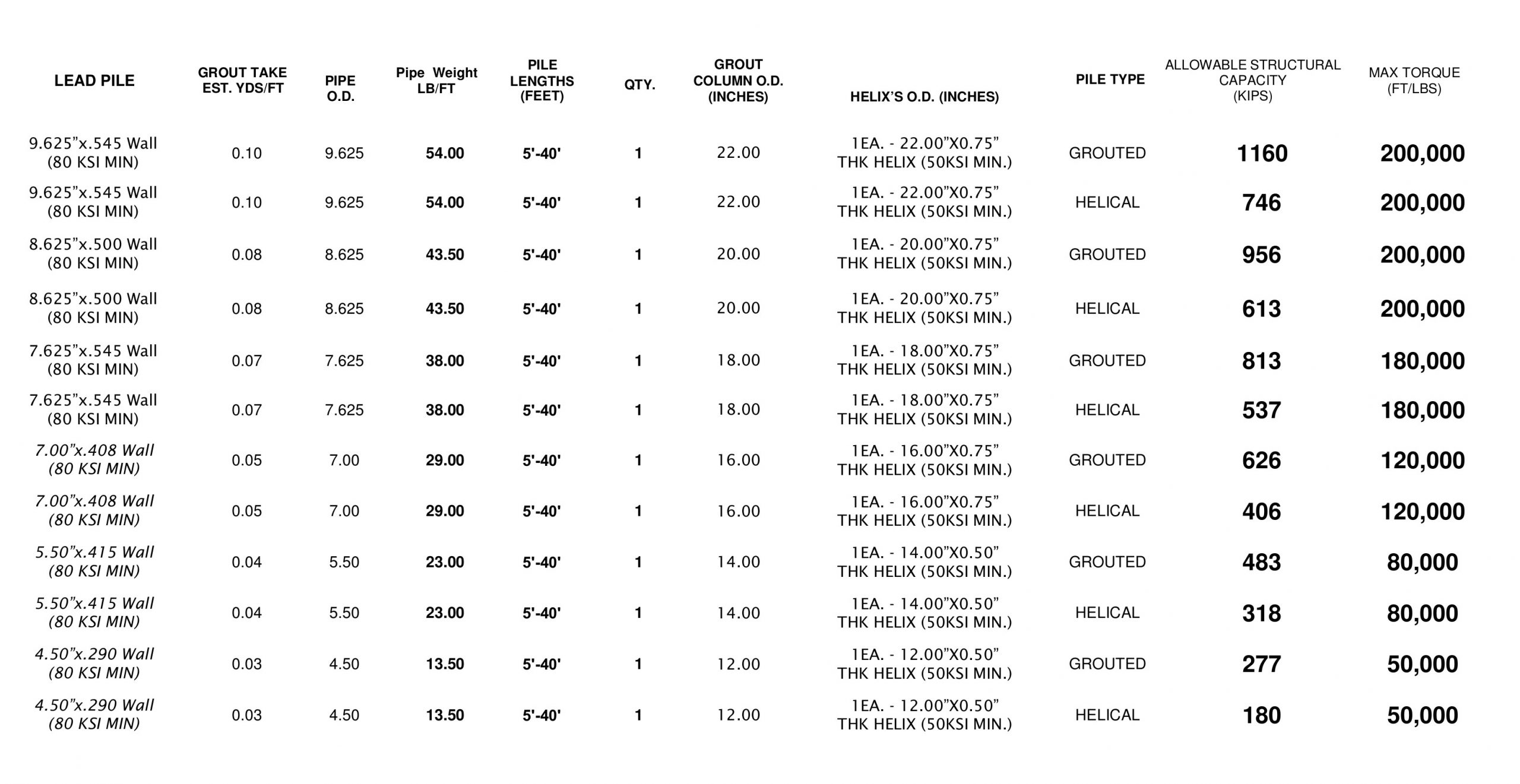

Pileworks has provided preliminary estimates of the torque-to-capacity empirical correlation factor, Kt, for helical pile shaft sizes we commonly manufacture. The machine torque measured during installation of a helical pile provides an indication of changes in soil resistance, and indirectly, the bearing resistance of the pile. There have been numerous studies of the relationship between installation torque and axial pile resistance, or geotechnical capacity, by both practitioners and scholars. However, the simplest and most commonly applied correlation as reported in the recently-released Deep Foundations Institute (DFI, 2019) Helical Pile Foundation Design Guide is as follows:

Qt = KtT

where, Qt = ultimate capacity of helical pile

Kt = capacity-to-torque correlation factor

T = average installation torque (taken at 1-ft increments over the final 3 ft of installation)

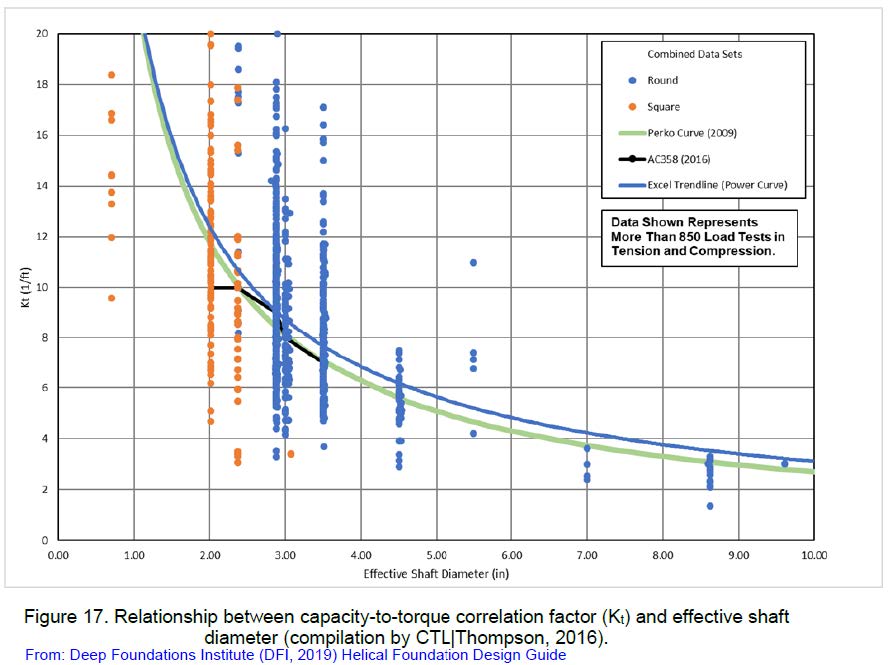

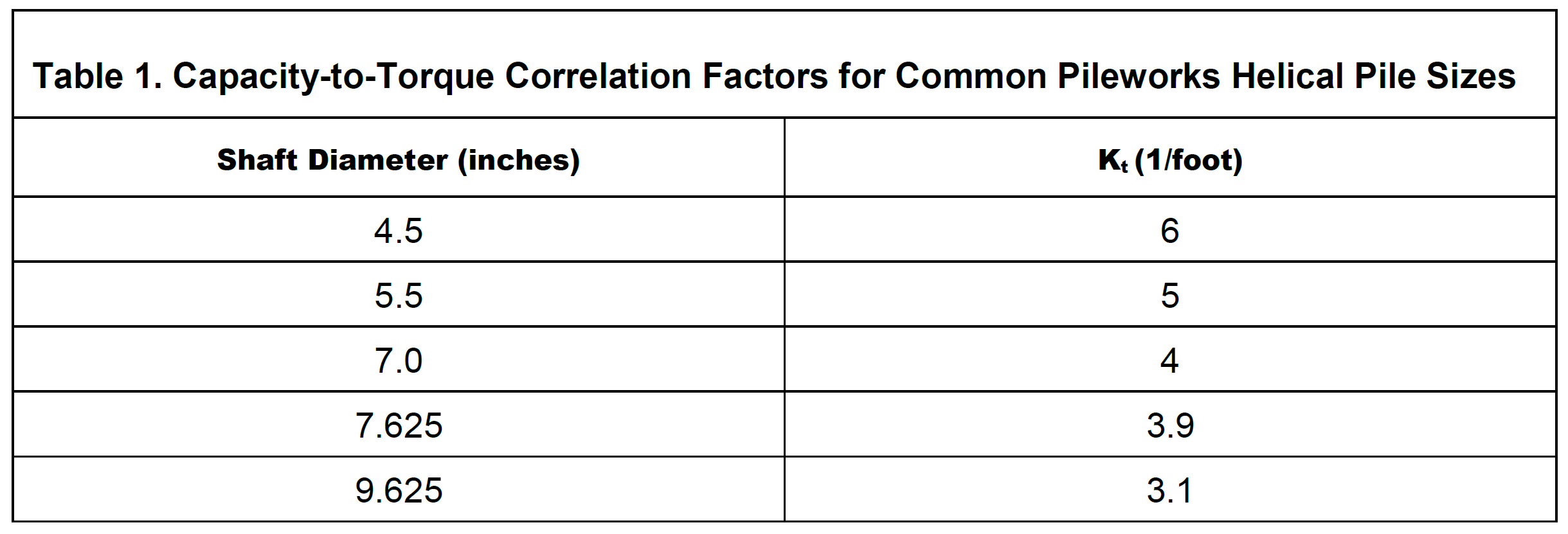

A plot of Kt vs shaft diameter from the DFI design guide is repeated below. Based on this figure, the Kt values for common Pileworks shaft sizes are provided in Table 1.

It should be stressed that the database used to develop these Kt correlations contains considerable scatter, was developed from pile diameters statistically on the small end or smaller than most Pileworks diameters, and covers a limited variety of subsurface conditions. These empirical correlations are not applicable for grouted piles, piles bearing on bedrock or highly overconsolidated soils, very deep or very shallow installations, and where the bearing plate is near a contact of markedly different soils. Until site-specific or geology-specific torque-to-capacity ratios based on load testing can be developed for the pile geometry being considered, use of a factor of safety of 3 or more is commonly applied to estimates of capacity based solely on installation

torque. In all applications, a subsurface exploration and design by a qualified geotechnical engineer is highly recommended. The DFI helical pile design guide contains additional discussion of the application of empirical torque-to-capacity factors and suggestions for load testing. Jacobs’ geotechnical engineers also can provide suggestions on a case-by-case basis.